Suchen

Weiterführende Links- Telefon: +1 (513) 771-7374

- Europa: +39-0376-389311

- E-Mail: PELabellers@ProMachBuilt.com

ProMach ist Ihr Partner von Anfang bis Ende. Unsere Produktmarken sind in verschiedene Geschäftsbereiche unterteilt, die für unsere Kunden am sinnvollsten sind, und decken alle Funktionen der Produktionslinie ab: Abfüllen, Abfüllung & Verschließen, Dekorative Etikettierung, Flexibles & Trays, Pharma, Produkthandling & Sterilisieren, Etikettieren & Codieren, Robotik & End of Line, und Systeme & Integration.

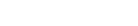

Erfahren Sie mehrSimpl-Cut’s unique features result in up to 6% increase in annual production, reported by our customers who regularly use the machine.

| ROLL-FED | SIMPL-CUT | |

|---|---|---|

GLUE APPLIED BEFORE CUTTING ALWAYS CLEAN DRUM |

Glue on the drum causes production slowdowns and machine stoppages. |

Allows higher speeds. No machine blockages or jams. No downtime for drum cleaning. |

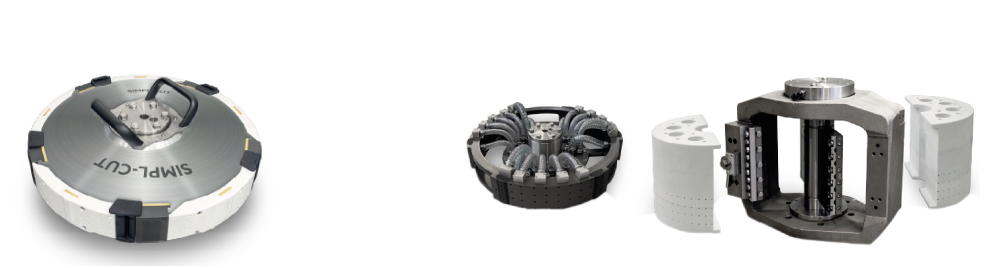

UP TO 6 DIVISIONS ON THE DRUM MAXIMUM FLEXIBILITY AT THE RIGHT SPEED |

Fixed number of divisions on the drum (3 or 4). Less management flexibility. |

Each container is labeled at its ideal speed. Use of 3, 4, 5, or 6 divisions on the same drum. Maximum management flexibility. |

STRESS-FREE LABEL UNWINDING OPTIMAL MANAGEMENT |

Greater stress on the film due to the use of a pneumatic mechanical arm. |

Optimal label management even with thinner films. |

INNOVATIVE BLADE HOLDER CARTRIDGE CLEANING DURING PRODUCTION |

Complex blade holder cartridge replacement process: requires highly skilled maintenance personnel and leads to significant production downtime. |

Tool-less blade holder cartridge, easily inserted and ready for production: during production, operators can restore and clean the removed seams at their own pace without reducing productivity. |

| ROLL-FED | SIMPL-CUT | |

|---|---|---|

STANDARD ERGONOMIC LAYOUT MAXIMUM EFFICIENCY |

Non-ergonomic standard layout. Less accessibility. Lower operator safety. |

Extremely easy machine access. Increased operator safety. Standard ergonomics: economic savings. |

FULLY INNOVATIVE LABELING UNIT PROTECTION INSPIRED BY THE CONCEPT OF TOTAL ERGONOMICS |

Traditional labeling unit protection, not fully ergonomic, which does not allow this level of space opening. |

A single protection that, in addition to lifting/lowering, rotates laterally, thus freeing the operator's working area. |

INNOVATIVE EXHAUST HOOD INSPIRED BY THE CONCEPT OF TOTAL ERGONOMICS |

Traditional fume exhaust hood, not fully ergonomic, which does not allow this wide space opening. |

The fume exhaust hood moves together with the protection, acting as a single unit without posts or covers, extremely easy to handle. |

FULLY INNOVATIVE JOG INTEGRATED INTO THE PANEL |

Traditional jog, not fully ergonomic, which does not allow this extreme maneuverability. Equipped with a spiral cable that tends to get dirty and damaged easily. |

The jog is integrated into the panel on the unit, without a spiral cable: this way, the jog moves with the panel and no longer gets in the way. |

| ROLL-FED | SIMPL-CUT | |

|---|---|---|

A SINGLE DRUM ZERO MAINTENANCE |

Complex label transfer setup, costly cutting drum maintenance. |

Elimination of label transfer. Quick format changes. No cutting system maintenance. |

INNOVATIVE CUTTING SYSTEM IMMEDIATE BLADE CHANGE IN 10" |

Complex blade replacement requiring specialized technical intervention. |

Easy blade replacement: simple operation that any operator can perform. |

INNOVATIVE GLUE ROLLER "ZERO SURPRISES" SYSTEM |

Traditional glue roller that does not allow such ease of use: damaged components cause unplanned stops, which are costly in terms of production loss. |

A single ready-to-use cartridge allows maintenance to be completed as quickly as possible, without surprises. |

VISIBLE FILTERS VISIBLE EFFICIENCY |

Traditional filters, often difficult to access, causing efficiency loss as their wear condition is not visible. |

All filters are mounted in transparent casings and are fully visible, without the need for disassembly. |

INNOVATIVE PNEUMATIC AND ELECTRICAL SYSTEM SEPARATED FROM EACH OTHER |

Typically, pneumatic and electrical systems are not separated: this makes troubleshooting, maintenance, and periodic inspections much more difficult and costly. |

Electrical and pneumatic systems remain separate, with key components positioned near the user. This facilitates troubleshooting, maintenance, and periodic inspections. |

Two technologies, one machine.

Simpl-cut® offers the flexibility to utilize two different technologies on a single station: roll-fed with hot glue and pre-glued linerless labels

Unmatched flexibility to adapt to production needs

Change from one technology to another in less than 10 seconds using the same drum

Capable of heat shrink, wrap-around labeling, increasingly requested by the beverage and mineral waters markets